The new European battery regulation: requirements and objectives

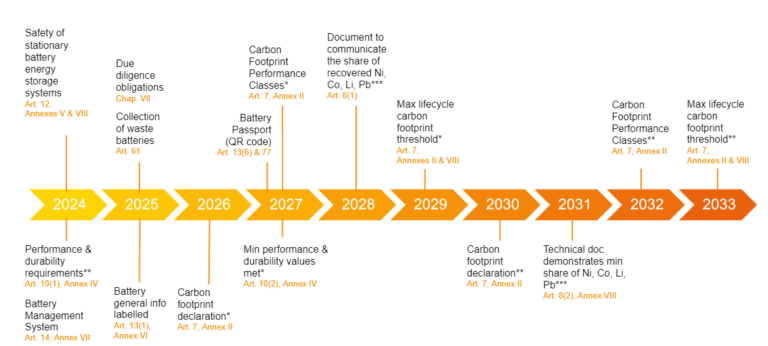

Gradually since June 2023, the European Battery Regulation will replace the existing 2006 directive (2006/66/EC). This implementation, which is being carried out in a synchronized manner across all member states of the European Union, aims primarily to reduce the negative environmental impacts associated with battery use (from portable and automotive batteries to batteries for electric vehicles).

This regulation aims to ensure the sustainability of batteries throughout their entire life cycle, from material extraction to recycling and reuse. It aligns with the objectives of the European Green Deal and is the first European legislative text to incorporate the complete life cycle of batteries.

The battery passport and QR Code: a detailed digital document

One of the major innovations of this regulation is the introduction of the “battery passport” in February 2027. This digital document, equipped with an identification QR code, will provide detailed information on each battery, including its chemical composition, manufacturing date, and possible recycling methods. This passport will ensure the compliance of batteries with traceability and safety standards.

The CE marking: affirming battery compliance with EU requirements

Additionally, the CE marking, which will become mandatory for all batteries starting in August 2024, will certify their compliance with the EU’s safety, health, and environmental protection standards. Concurrently, a Battery Management System (BMS) must be integrated into each battery from August 2024, allowing for precise monitoring of its health status.

The BMS: evaluating battery health

The new European Battery Regulation introduces significant requirements concerning Battery Management Systems, commonly known as BMS. These systems play a crucial role in managing battery performance and safety, especially in the context of new environmental and sustainability standards.

- Monitoring, managing battery health, and risk prevention: the BMS is essential for monitoring the State of Health (SOH) and State of Charge (SOC) of the battery. This means it continuously evaluates the remaining capacity and resistance of the battery, ensuring optimal and safe usage.

- Compliance with environmental requirements: with a focus on sustainability and carbon footprint, the BMS helps optimize battery usage, prolonging its lifespan and reducing the need for raw material extraction. This is particularly important for the goals of the European Green Deal, which aims to minimize the environmental impact of batteries.

- Performance optimization: the BMS is also crucial for maintaining the balance between battery cells, thereby optimizing overall performance and energy efficiency. This not only enables better energy management but also ensures a more economical and eco-friendly operation of batteries.

Battery manufacturers will need to integrate sophisticated BMS into their products to comply with these new regulations. This implies investments in research and development to create battery management systems that not only meet regulatory requirements but also offer added value in terms of battery performance and sustainability.

Environmental requirements and carbon footprint: for a circular and sustainable economy

The new European Union regulation on batteries will emphasize the importance of the carbon footprint, a crucial indicator calculated through a life cycle analysis. All battery models will be required to provide a declaration of their carbon footprint, reflecting the EU’s commitment to a circular economy and comprehensive consideration of the environmental impact of batteries at all stages of their life.

Moreover, starting from 2025, the regulation will gradually introduce new requirements. This includes specific declarations, the establishment of performance classes, and the definition of maximum limits for the carbon footprint.

These requirements will apply not only to electric vehicle batteries but also to batteries used in light means of transport, such as electric bikes and scooters, as well as rechargeable industrial batteries.

This regulatory evolution marks a significant step towards reducing the environmental impact of batteries and promoting sustainable practices within the industry.

Due diligence and recycling

Starting in 2025, a new era in battery management will begin with the introduction of significant measures under European regulation.

Manufacturers will be required to implement a duty of diligence focused on assessing and addressing the social and environmental risks inherent in the supply chain of materials used in batteries. This initiative aims to promote responsibility and sustainability in the industry.

In parallel, the regulation will set ambitious targets for recycling and material recovery, particularly for end-of-life batteries. Starting in 2025, specific targets regarding recycling efficiency, material recovery, and the share of recycled content in batteries will be progressively implemented.

The goal is to ensure that all used batteries are efficiently recycled and that critical materials such as cobalt, lithium, and nickel are recovered at a high level. This approach is part of the effort to promote a circular economy by ensuring that valuable materials are reused, thereby reducing the overall environmental impact of batteries.

Forsee Power’s response to the European battery regulation

Forsee Power, a leader in battery systems for electromobility, is aware of the importance of these regulatory changes and has been actively committed to complying with these new standards since its founding in 2011. The Group is already advanced in meeting several regulatory requirements and has been ahead of others in many aspects.

The BMS: an integrated tool in our batteries long before battery regulation

At Forsee Power, innovation and quality are at the heart of our mission, which has driven us to adopt this advanced technology from the start of our activities, whether for heavy vehicles or light vehicles. By monitoring key parameters such as temperature, voltage, and current in real-time, the BMS allows us to verify the health of the batteries integrated into our customers’ vehicles.

By anticipating regulatory requirements, we have not only ensured the compliance of our products but also reinforced our position as a leader in the smart battery sector.

A responsible supply chain

At Forsee Power, we are firmly committed to a local supply chain, in line with our values of sustainability and environmental responsibility.

As part of this approach, we select local suppliers, thereby promoting the economic development of surrounding communities while minimizing the environmental impact associated with the transportation of components necessary for the manufacture of our batteries for light and heavy vehicles.

With an industrial presence on three continents (Europe, Asia, and America), we strive to serve our local customers as closely as possible. This approach not only allows us to effectively meet their specific needs but also contributes to reducing the carbon footprint by limiting the distances traveled by our products.

Eco-Design: durability beyond measure

Forsee Power places great importance on adopting sustainable practices from the earliest phases of product development: from the initial design to final recycling.

Wherever possible, Forsee Power teams prioritize the use of materials from renewable sources and design battery systems so that components are easily accessible and detachable for maintenance operations.

A committed life cycle analysis

Our CSR engineers, dedicated to this environmental mission, work closely with various key departments of the Group. Their goal is to provide a comprehensive assessment of the carbon footprint associated with each battery in our product portfolio, whether for heavy or light vehicle solutions.

This meticulous life cycle analysis of batteries involves a thorough examination of each stage, from the extraction of raw materials to the end of the battery’s useful life.

By gathering precise data on greenhouse gas emissions, energy consumption, and other environmental factors, we can quantify and compare the carbon footprint of different battery technologies. This transparency allows us to direct our efforts towards more sustainable solutions and help our customers make informed decisions regarding electric mobility.

At Forsee Power, we firmly believe in our responsibility towards the environment and continuously strive to improve the sustainability of our products. The life cycle analysis of batteries is an essential component of our commitment to a cleaner and more sustainable future for all.